Cracking the Code: Reverse Engineering the Antikythera Mechanism with Ancient Greek Tools

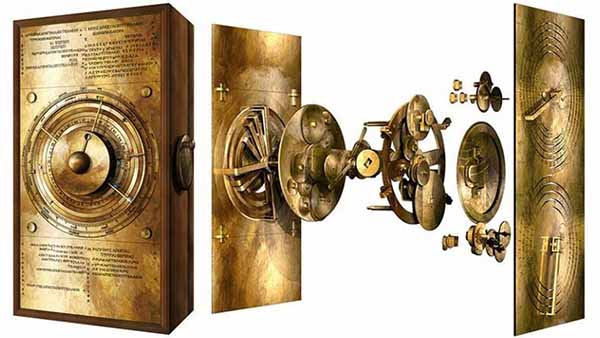

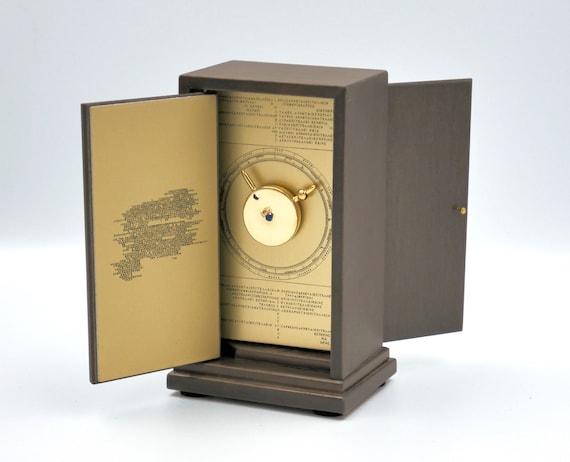

The Antikythera Mechanism. Even the name whispers of forgotten knowledge, of astronomical secrets locked within corroded bronze gears. For decades, this device, recovered from a Roman-era shipwreck off the Greek island of Antikythera, has captivated researchers and fueled speculation. Was it an alien artifact? A gift from a more advanced civilization? Or, as I believe, is it a testament to the ingenuity and skill of the ancient Greeks, a level of technological sophistication we’ve drastically underestimated?

My name is Elias Thorne, and I'm a materials scientist and mechanical engineer obsessed with answering that question. I've spent years dissecting the mechanism's design, analyzing the composition of its bronze alloys, and studying the tools and techniques available to artisans in ancient Greece. My goal is simple: to understand how they could have built it, not just what it did. And I believe the key lies in reverse engineering the manufacturing process using only the tools and knowledge accessible at the time. Forget lost knowledge; let’s focus on lost craftsmanship.

The Challenge: Precision Manufacturing Without Modern Machinery

The core challenge, of course, is precision. The Antikythera Mechanism is not a crude assemblage; it's a complex, intricately geared device. Modern CNC machines can churn out gears with micron-level accuracy. The ancient Greeks had… muscle power and a few hand tools. How did they achieve the necessary tolerances to make such a device function? This is where things get interesting.

Take Gear B1, for instance. A seemingly simple 64-tooth gear, but replicating it with ancient techniques is a herculean task. I've been focusing my experimental archaeology project, running on a ridiculously overburdened Raspberry Pi analyzing finite element simulations, on exactly this problem. Let's break it down.

Replicating Gear B1: A Hypothetical Journey

First, the mold. We're talking lost-wax casting, a technique well-established in ancient Greece. But achieving the required accuracy for the gear's teeth demands a highly refined mold material. My hypothesis centers around using a mixture of very fine river clay – I've been experimenting with clay from the Ilissos riverbed in my reconstructions – tempered with finely ground terracotta shards for thermal stability. Adding powdered charcoal further improves gas permeability during the casting process.

The wax model itself would be meticulously carved. Creating the negative space for each tooth precisely would necessitate bronze or even tempered iron tools, and the use of calibrated templates.

Next, the bronze. Forget modern alloys; we're working with what they had: locally sourced copper ore and tin. Achieving the desired metal purity – I'm aiming for a bronze alloy of around 88% copper, 10% tin, and 2% trace elements like lead and arsenic (a common impurity that also improves castability) – requires repeated smelting and refining. This is laborious, time-consuming, and prone to error, but crucial for a strong, durable gear.

Casting is just the beginning. The raw casting would be far from perfect. Post-casting finishing is critical. This involves a foot-powered lathe, inspired by descriptions from Hero of Alexandria. While not as precise as a modern lathe, with carefully crafted tools and a skilled operator, it could be used to refine the gear's profile and smooth the tooth surfaces.

Achieving perfectly even tooth spacing would be almost impossible without modern dividing engines. My working hypothesis involves a system of calibrated bronze templates. Imagine a master template with precisely spaced notches corresponding to each tooth. This template could be used as a guide for filing each tooth individually. It would be slow, painstaking work, requiring meticulous attention to detail and a good magnifying lens, but achievable.

And what about shrinkage during casting? Modern simulations allow us to predict and compensate for this. The ancient Greeks, of course, didn't have finite element analysis. Instead, they would have relied on empirical observation and iterative refinement. The first mold would be deliberately oversized. After casting, the gear's dimensions would be carefully measured. The mold would then be adjusted based on the observed shrinkage, and the process repeated until the desired dimensions are achieved. Trial and error, but informed trial and error.

Building the Brain: Assembling the Antikythera Mechanism

The gears, of course, are only part of the story. The dials, the housing, the intricate inscriptions – all presented unique challenges.

The housing, for example, would likely have been crafted from aged olive wood, carefully seasoned for years to minimize warping. Traditional mortise-and-tenon joinery, combined with bronze pins, would provide a strong and stable structure. Creating the finely graduated scales on the dials demands immense skill. My research suggests a combination of incised lines and applied silver inlays. The incised lines would be carefully marked using a compass and straight edge, then deepened with a fine chisel. The silver inlays would then be hammered into these grooves, creating a visually striking and durable marking.

The assembly process is where precision truly matters. Even with carefully crafted components, slight variations are inevitable. To compensate, I hypothesize the use of shims – thin sheets of hammered bronze – to adjust the center distances of the gears and minimize backlash in the gear train. Friction, of course, would be a major concern. A lubricant derived from rendered beeswax and olive oil would help to reduce friction and ensure smooth operation.

Implications and Revelations: More Than Just Clockwork

What if we can successfully replicate the Antikythera Mechanism using only ancient Greek tools and techniques? What does that tell us?

First, it suggests that the ancient Greeks possessed a far deeper understanding of materials science, mechanics, and astronomy than we often give them credit for. It points to a continuous tradition of practical experimentation, of iterative refinement, that has been obscured by the focus on theoretical philosophy.

Second, it highlights the importance of tacit knowledge. The unwritten, hands-on expertise that is essential for successful craftsmanship. We can study the tools and techniques, but without the accumulated experience of generations of artisans, we will struggle to replicate their achievements.

It may also point to a darker truth; that this level of advancement was suppressed. Perhaps the knowledge was deemed too dangerous, threatening the established order. The idea of having the stars at your fingertips, the ability to accurately predict celestial events, could indeed have been revolutionary in a world where such things were often interpreted as divine will. The loss of this technology could then be seen not as accidental, but deliberate.

Of course, any reconstruction is speculative. We are limited by the available archaeological evidence. But by engaging in practical experimentation, by attempting to recreate the Antikythera Mechanism using the resources available to the ancient Greeks, we can gain a deeper appreciation for their ingenuity and resourcefulness. We can unlock the secrets of their craftsmanship, and perhaps, uncover a hidden chapter in the history of technology. The ancient Greeks may not have had CNC machines, but they had something just as powerful: human ingenuity and a relentless desire to understand the world around them.